Your cart is currently empty!

Paper Shredder Replacement Parts

Document Dynamix Australia can promptly supply these spare parts or quickly supply and fit at your office by placing a service call. Simply call 1800 874 733 or use the form on this page to place a service call or contact us about a replacement part. When placing a service call, please first write down your paper shredders brand, model and serial number. The serial number can normally found on the manufacturers rating plate often placed on the rear, front or top of the shredders door. Some of the paper shredder spare parts we have available:

Auto Feed Intake Rollers

Motor Drive Gears

Buffer Gears

Gear Wheels & Belts

Paper Shredder Electrical & Electronic Components

Synchronising Gears

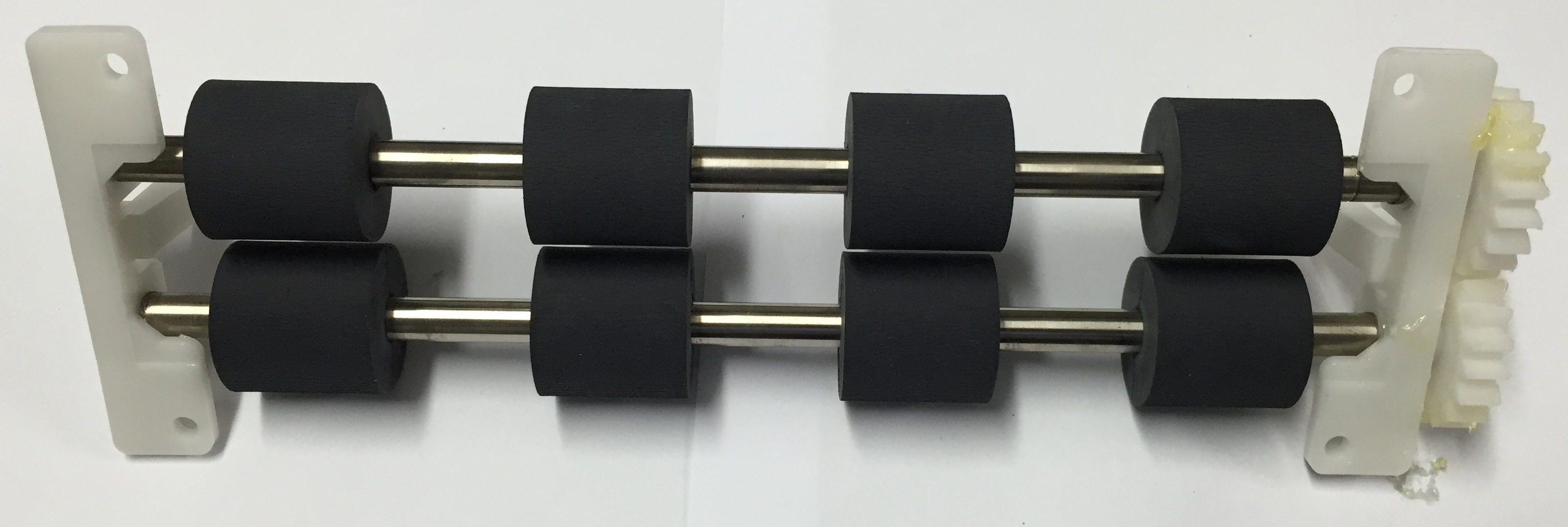

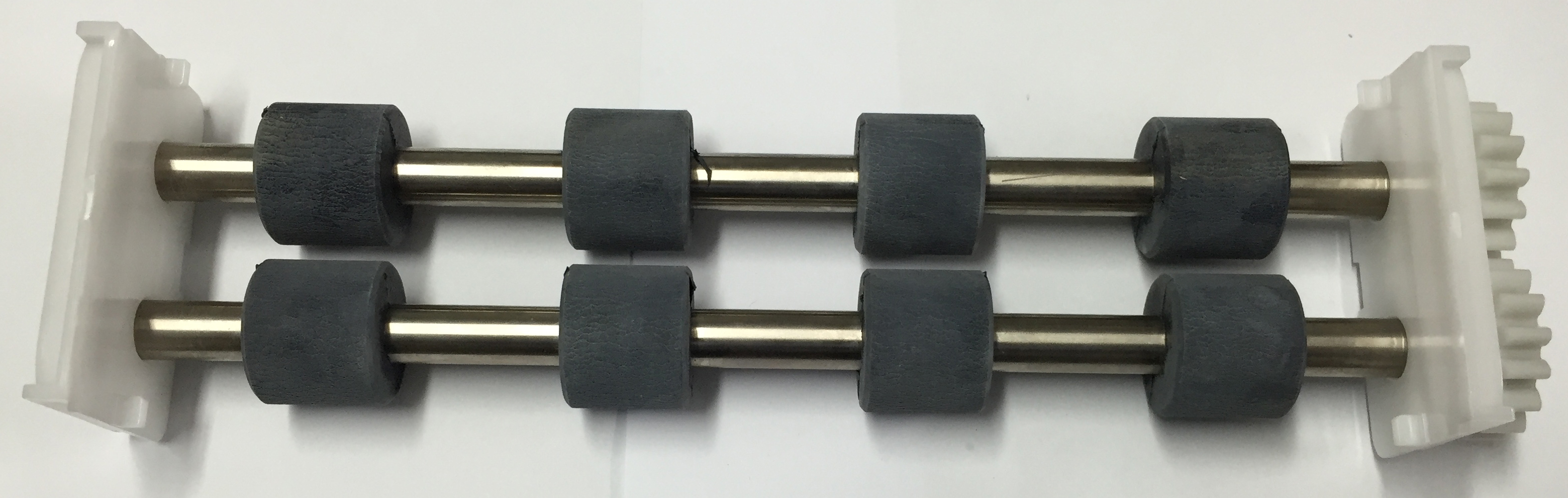

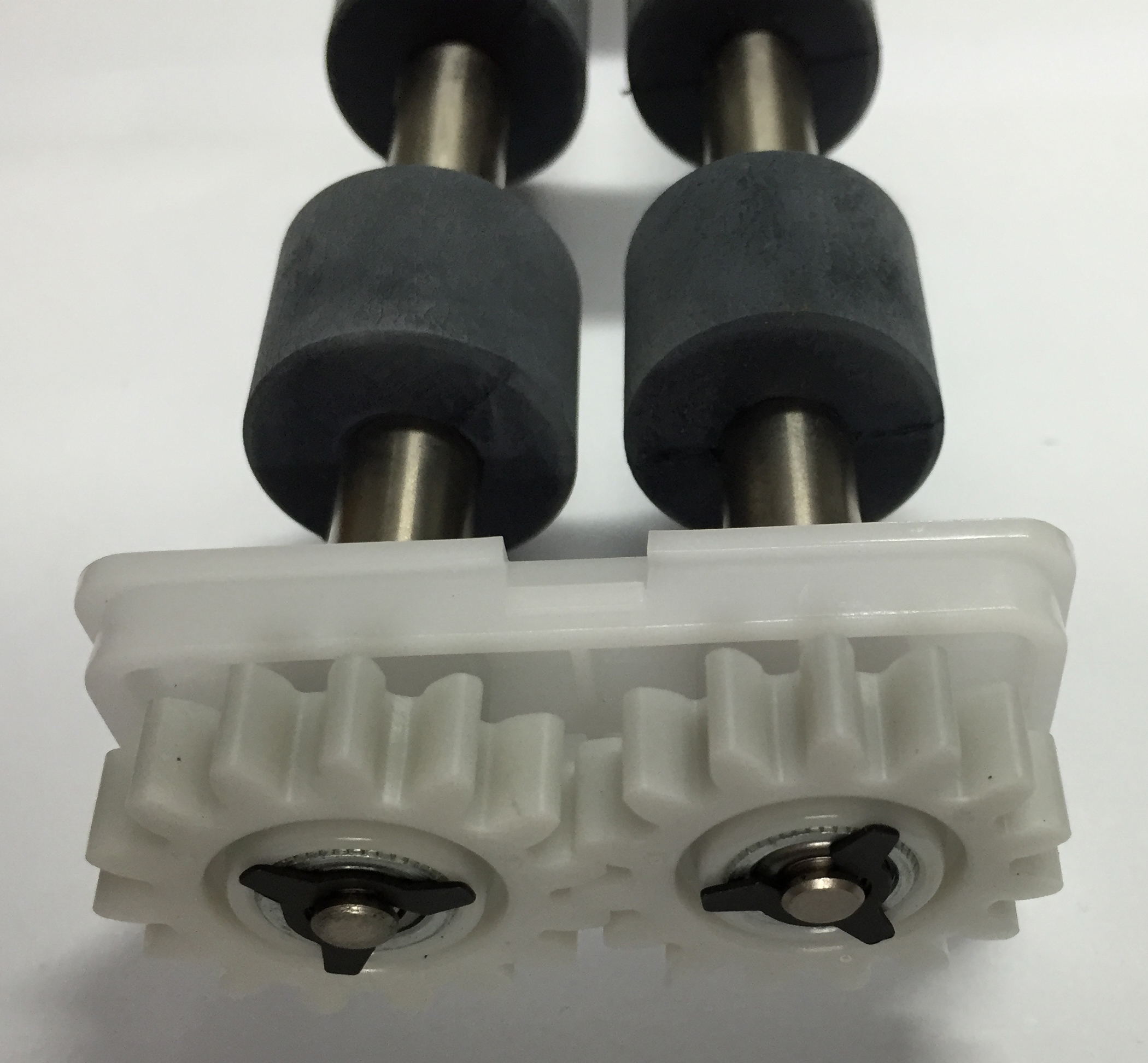

Auto Feed Intake Rollers

Paper Shredder Auto Feed Intake Rollers will wear out over time. Being manufactured of mid-density rubber compound, like tyres on a car they won’t last forever and can also perish. When your shredders auto feed rollers are worn, this will negatively impact the operation of the auto paper feeding unit. Over time, users notice miss-feeding will become more frequent with a gradual decline in operation as the rollers become more worn. With normal operation, the auto feeders rollers develop a shiny appearance and in some cases with parts cracking and falling off as they become perished. The diameter of feed rollers becomes smaller as they deteriorate which shortens the feed distance per feed cycle, this slows or even stops the auto feeder from properly operating. As the rollers wear, auto feeding a stack of paper takes longer and longer with eventual non-operation of the auto feeder assembly.

Replacing your Auto Feed paper shredders feed rollers, will restore your machine’s operation back to normal. Shredding through a stack of papers will happen faster and eliminate miss feeds and unnecessary paper jams.

Supply & Fit Auto Feed Rollers

We also offer fitting of auto feeds rollers and can perform service calls to get your shredder performing like new again. If you think your shredder needs new rollers, contact us for free advice and support.

Rexel / Swingline Auto Feed Rollers

Models: Auto+ 250x, Auto+ 300x

Models: Auto+ 500x, Auto+ 750x

Models: Auto+ 500, Auto+ 650

Rexel Optimum Models: 50X 100X 100M 150X 150M 225X 225M 300X 300M 600X 600M 750X 750X. Also available for and Leitz Autofeed.

We can also supply Boxis Auto Feed Rollers, KOBRA Auto Feed Rollers, Fellowes Auto Feed Pick Ups & much more!

Motor Drive Gears

Motor drive gears can fail without warning. This gear is sometimes referred to as the slant gear, stage 1 gear & stage or two combined gear. Typically paper shredders gearing failures are almost always identified when the machines runs but paper will not feed due to the cutter shaft blades not rotating. For this application, these gears are commonly manufactured using a tough polymere material providing good durability, high reliability and quiet operation producing minimal drive whine. Over time, gears can become fatigued especially if a shredder has been jammed repeatedly, eventually stripping out and rendering the machine faulty. Every time a shredder is jammed, this gear is exposed to the most shock being the first gear driven from the motor armature drive shaft. In extreme cases, the motor armature shaft can become bent with the entire motor also requiring replacement. Some paper shredders use a “Sacrificial Gear” to protect components from the motor through to the synchronising gears which act as the final drive for the cutter shafts.

Replacing broken shredders gears restores the connection between the motor to the entire drive train with normal operation restored.

Tip! Oiling your shredder’s blades also reduces unnecessary load on your shredders gears, increases performance, energy efficiency and reduces noise whilst in operation.

IDEAL / EBA / Fellowes / SEM / Destroyit / GBC / Fordigraph / Rexel / Swingline Motor Drive Gears

Models: 2404, 2501, 2502, 2503, 3104, 1524, 2125, 2127, 2326, 2331, 2339, 3140, 4002

Buffer Gears

Buffer drive gears are designed not only to drive but also to absorb the shock caused by paper jams, protecting the drive train when this happens. Although a buffer drive gear is designed to absorb potentially damaging shock from paper jams, over time, this shredders gear can fail without any notice. This gear is often placed before the synchronising gears, acting as the final drive before the cutters. No matter the brand of paper shredder, all drive gear faults are commonly diagnosed if the machine runs but shredding blades do not rotate. The buffer gear is not designed as a “Sacrificial Gear” however this gear is still found to fail when subjected to excessive paper jams which is a good thing as the rest of the drive train is preserved.

Replacing broken shredder gears will most likely fix this problem with normal operation.

Tip! Oiling your shredder’s blades also reduces unnecessary load on your shredders gears, increases performance, energy efficiency and reduces noise whilst in operation.

IDEAL / EBA / Fellowes / SEM / Destroyit / GBC / Fordigraph / Rexel / Swingline Motor Drive Gears

Models: 2404, 2501, 2502, 2503, 2600, 2601, 2602, 2603, 3104, 1524, 2125, 2127, 2226, 2231, 2239, 3140, 4002

Back to top

Gear Wheels & Belts

Fellowes, Intimus, Simplex, GBC Shredmaster, Gear Wheels & Belts

This gear set consists of the motor drive gear and cutter gear. The motor drive adopts a toothed belt arrangement driving from the motor to a stage 1 & 2 combined tooth/cog gear which in turn, drives the cutter shaft gear. The cutter shaft gear drives the cutter shafts using a roll pin inserted through the main cutter shaft to engage. There is 45 degrees free rotation when changing direction which is deliberately designed to free paper jams without lock up. As already mentioned, all drive gear faults are commonly diagnosed when the shredder operates but the shredding shafts don’t turn. This is not designed as a “Sacrificial Gear” however this gear can still fail caused from repeated paper jams becoming fatigued over time. Sometimes the gear is not damaged but the roll pin has just broken. This is easily fixed by punching out the old roll pin and inserting a replacement which is also included in a “Cutter Gear Kit”.

Replacing broken shredder gear wheels will most likely restore your shredders correct operation.

Tip! Oiling your shredder’s blades also reduces unnecessary load on your shredders gears, increases performance, energy efficiency and reduces noise whilst in operation.

Fellowes / Intimus / Simplex / GBC Shredmaster Gear Wheels

Models: 110, 385se, Simplex, 4022s, 4122x, 4038s, 4038-S1

Paper Shredder Electrical & Electronic Components

Your office shredder can fail without warning due to electronic or electrical failure, which often happens when you need to shred the most. Unfortunately, electronic and electrical components are similar to a light bulb, suddenly failing without any warning. A paper shredder consists of many electronic and electrical parts including auto start/stop sensors, bin full switches and sensors, doors switches and sensors, PCB’s, oil pumps, motors, capacitors, paper thickness mercury and jam stopper sensors to mention a few. Throughout all shredder brands, most use similar parts listed above for the same purpose. Although spare parts are unique to different shredder brands, Document Dynamix Australia support most makes and models. Before calling for spare parts, we recommend you write down the brand, model and the serial number, normally found on the manufacturers rating plate and usually positioned on the rear, front or top of the shredders door.

All Shredder Brands – Fellowes, Powershred, Automax, Rexel, Auto+, Stack Shred, Swingline, Boxis, IDEAL, Auto+, DAHLE, EBA, Kobra, Fordishred, GBC, GBC Shredmaster, Twinlock, ACCO, Fordigraph, Destroyit, Intimus, Martin Yale, Ledah, Kelji, Safeguard, Panasonic, ROTO, Geha.

Synchronising Gears

Synchronising gears are usually reliable however can fail due to lack of lubrication, typically caused by lack of preventative maintenance. As with other parts in the gear train, a broken synchronising gear can be diagnosed by the shredder operating but one or both of the cutter shafts not rotating. The synchronising gear attached to the driving shaft is subject to the most load and often the first to fail when used over prolonged periods under heavy loads without adequate lubrication. There are other factors that can cause synchronising gears to break including worn cutter shaft bearings & bushes and even bearing housings that have receded.

Replacing broken synchronising gears will most likely fix this problem with normal operation.

Tip 1: Oiling your shredder’s blades also reduces unnecessary load on your shredders gears, increases performance, energy efficiency and reduces noise whilst in operation.

Tip 2: When replacing synchronising gears on cross cut paper shredders, the cutter shafts have to be “Re-Timed’ to maintain the proper “Cross Cut” action. Please feel free to contact us for free technical advice.

All Shredder Brands – Fellowes, Powershred, Automax, Rexel, Auto+, Stack Shred, Swingline, Boxis, IDEAL, Auto+, DAHLE, EBA, Kobra, Fordishred, GBC, GBC Shredmaster, Twinlock, ACCO, Fordigraph, Destroyit, Intimus, Martin Yale, Ledah, Kelji, Safeguard, Panasonic, ROTO, Geha.