Your cart is currently empty!

Paper Shredder Cutter User Maintenance – Lubrication Cleaning Oil Sheets Application

Using Shredder Oil Sachet Sheets is the easiest, cleanest and fastest way to apply Shredder Lubrication/Cleaning oil to your paper shredder. These very popular individual sachet sheets are impregnated with oil that once shredded, release the lubricant directly onto the cutting cylinders. This eliminates any mess and is extremely effective. With Shredder Oil Sheets, there is no need to keep the oil away from the Auto-Start/Stop sensors as the oil is contained within the sachet sheet. Auto-Start/Stop sensors can attract dust if they have oil on them, being the cause of unnecessary malfunction but this is no problem when using Shredder Lubrication/Cleaning oil sachet sheets.

Using Shredder Oil Sachet Sheets is the easiest, cleanest and fastest way to apply Shredder Lubrication/Cleaning oil to your paper shredder. These very popular individual sachet sheets are impregnated with oil that once shredded, release the lubricant directly onto the cutting cylinders. This eliminates any mess and is extremely effective. With Shredder Oil Sheets, there is no need to keep the oil away from the Auto-Start/Stop sensors as the oil is contained within the sachet sheet. Auto-Start/Stop sensors can attract dust if they have oil on them, being the cause of unnecessary malfunction but this is no problem when using Shredder Lubrication/Cleaning oil sachet sheets.

Use of Shredder Oil Sheets is becoming the preferred method of application and will overtake the conventional bottled oil in the not too distant future.

There are several factors that determine how often your shredder should be oiled such as the type of paper being shredded, the amount of paper being shredded and the frequency of use – daily or occasional use. Cross Cut shredders require more frequent oiling but as a guide, it is recommend you oil your shredder each time it is emptied. If your shredder is used in a business or government office where it may be emptied more than once a week, it is best to get into the habit of oiling your shredder weekly or more when used more heavily than usual. Putting a reminder in your outlook is a good way to ensure you shredder is oiled when it should be.

Many people are under the impression that Shredder Lubrication/Cleaning oil is used for lubricating your shredders cutters and is the reason for improved performance, but lubrication is really a secondary reason for the application of Shredder Lubrication/Cleaning Oil.

Shredder oil has a water like viscosity which works well for quickly soaking into debris and dust that accumulates between the shred discs. The shred discs are placed at very close tolerances between each other and don’t actually touch, but the space between will eventually fill with debris and dust resulting in poor shredding performance, labouring your shredder.

Proper application of Shredder Lubrication/Cleaning Oil will clear this accumulation of debris and dust and restore your shredder to perform how it should. Your shredder will shred more freely and handle paper and discs with much less effort.

Proper Lubrication/Cleaning of a shredders mechanism restores your shredders performance, reduces noise, helps shred discs more easily, enhances reliability, reduces paper jams, enhances overall operational performance and efficiency and prolongs the life of your shredder.

It’s mainly due to the removal of the debris and dust in your shredders mechanism, that restores your shredders performance.

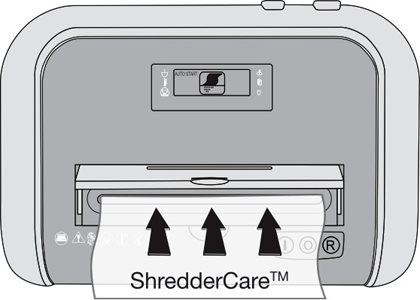

Following is the recommended proceedure for the application of ShredderCareTM lubrication/cleaning oil sheets:

Feed 2 oil sheets separately one after the other (or 2 oil sheets side by side separately per pass to cover the full width of wider paper feed entry when necessary) into the shredder. Once the oil sheets are completely shredded and the shredder stops, run in reverse for 2-3 seconds. Resume normal operation.

Dont’s of Oiling Your Shredder:

- Never apply penetrating oils/lubricants such as WD40/RP7 and the like.

- Never apply oil/lubricant dispensed from an aerosol container such as WD40/RP7 and the like.

- Do not use any petroleum-based oils or lubricants. Use of such lubricants could void the warranty on your shredder and could cause serious injury as they can be hazardous subatances when used with electronic devices.

- Other oils/lubricants such as WD40/RP7 can over time “bind up” your shredder with evaporated residue causing unnecessary failure.